Start Your Own Gold Mine

Start Your Own Gold Mine is investment project of GOLDIVANTI LP.

Start Your Own Gold Mine, authored by Mr. Jean Louis through RCD Wealth, is a comprehensive turnkey program designed as both consulting service and mentor-guided initiative that enables clients to commence gold mining operations within 45 days of company registration. This straightforward business model serves as an effective wealth generation plan aimed at achieving financial freedom with rapid returns on investment by equipping participants with essential skills in legalities, prospecting, assaying, technologyapplication for efficient scalability and practicality, competency in various gold recovery methods, site management techniques including the takeover of existing sites, and strategies to scale their mining business. Through this program’s integrated approach highlighted across multiple references it empowers individuals not only with tangible profits fromkilograms of extracted gold but also a deep understanding necessary to navigate both operational challenges and opportunities within the industry effectively.

We have started back in 2012 and 2013 our own first and small production of gold on the Namba Moja mining site of Captain Ngowi, former pilot of President Nyerere of Tanzania, close to Mgusu village and Geita town.

Today we have access to many rich mining sites where our clients may start their own gold mine.

We are developing mining sites in East Africa and worldwide.

Joint ventures and partnerships with local licensed mining site holders are welcome.

Startup in gold mining is possible already with US $22,000 with sharing option or with US $66,000 without sharing option.

- What is the first step a gold prospector should take when starting to search for gold?"

The first step a gold prospector should take when starting to search for gold is to research and obtain the necessary permits and knowledge about the area where they plan to prospect. This includes understanding local laws, regulations, and claiming processes, as well as gaining knowledge about the geological features and historical gold findings in the region. If you are looking for a more hands-on first step, it could be to gather the essential prospecting equipment, such as a gold pan, shovel, classifiers, and other basic tools needed for initial surface prospecting. - The Midnight Donkey Whisperer

A late-night gathering in a rural Tanzanian village takes an unexpected and humorous turn when a familiar face emerges from the darkness.

A late-night gathering in a rural Tanzanian village takes an unexpected and humorous turn when a familiar face emerges from the darkness. - The Transformative Impact of Wagagai Gold Mining on Busia, Uganda

The Wagagai gold mining project in Busia, Uganda, represents a monumental leap in the region’s economic and industrial development. As a mentor for the Start Your Own Gold Mine program, I highlight how this $200 million investment by Wagagai Mining (U) Limited—a subsidiary of China’s Liaoning Hongda Group—is set to revolutionize local employment, infrastructure, and value-added mineral processing, aligning with Uganda’s vision to end raw mineral exports and boost domestic refining capacity. - Mining Companies in East Africa

- Seeking Investments for Your Potential Gold Mining Site?

Seeking Investments for your potential gold mining site? Start Your Own Gold Mine emphasizes the crucial first step in attracting investment—investing personally into discovering and validating a viable mineral deposit. Before approaching external financiers or stakeholders with promises of lucrative returns, it's imperative that you invest time, effort, and resources to conduct thorough exploration activities such as geological surveys and sampling analyses. This initial self-investment is essential for establishing the credibility and potential profitability of your site by confirming its value in terms of resource quantity and quality. Once a valuable deposit has been identified through these preliminary efforts, it provides concrete evidence that can be presented to investors, thereby increasing their confidence in funding further development stages such as feasibility studies or full-scale mining operations. This approach not only secures the necessary capital for expansion but also establishes your credibility within the industry by demonstrating commitment and due diligence from inception. - Unlocking Hidden Riches: The Role of Geophysical Exploration in Gold Mining

Geophysical exploration has revolutionized the search for gold by allowing mining companies to non-invasively probe the Earth's subsurface and identify potential deposits with greater accuracy and efficiency. By utilizing a range of techniques such as magnetic, electromagnetic, induced polarization, resistivity, and seismic surveys, experts can detect anomalies and variations in physical properties that may indicate the presence of gold and its associated minerals. This cutting-edge approach not only accelerates the discovery process but also helps in minimizing environmental impact by reducing the need for exploratory drilling and minimizing the area that needs to be disturbed. As the quest for precious metals continues, geophysical methods stand as a cornerstone in the responsible and effective exploitation of gold resources worldwide. - Matrix Gold Prospecting: The Fastest Way to Start Your Own Gold Mine

Matrix Gold Prospecting is a streamlined, systematic approach designed to quickly identify gold deposits and initiate production with minimal delay. This method ensures rapid results while maintaining cost efficiency, making it ideal for small-scale miners looking to start operations within weeks rather than years. - Ground-based High-Resolution Proton Magnetometer Survey

A Ground-based High-Resolution Proton Magnetometer Survey is a sophisticated geophysical technique employed to detect subtle variations in the Earth's magnetic field, revealing potential subsurface mineral deposits, particularly gold ores. This method utilizes a proton magnetometer to precisely measure magnetic field strength, enabling accurate mapping of underground geological structures. This survey is a critical component of modern gold exploration, allowing for targeted and efficient extraction.

A Ground-based High-Resolution Proton Magnetometer Survey is a sophisticated geophysical technique employed to detect subtle variations in the Earth's magnetic field, revealing potential subsurface mineral deposits, particularly gold ores. This method utilizes a proton magnetometer to precisely measure magnetic field strength, enabling accurate mapping of underground geological structures. This survey is a critical component of modern gold exploration, allowing for targeted and efficient extraction. - Estimation of Soil Leachable for Gold Recovery Using 1000 Kilograms of Cyanide

The provided list consists of references and resources related to various aspects within the gold mining industry, particularly focusing on cyanidation (a process used for extracting precious metals like silver or gold from ore using a solution containing sodium cyanide), heap leaching methods in metal recovery processes such as CIL-CIP systems commonly employed by companies including Xinhai Mining and Anglo American, environmental considerations associated with mineral processing (like the Cyanide Code audit reports) alongside alternative technologies aimed at reducing or replacing traditional cyanidation techniques. These resources cover technical papers detailing heap leaching efficiency factors such as ore characteristics affect gold recovery rates; patents related to optimizing and decreasing sodium citrate consumption in sulfides for improved process economics, methods involving hydrogen peroxide use during the cyclones of precious metal extraction (like those studied by Kompleksnoe Ispolzovanie Mineralnogo Syra), as well practical guidelines from industry leaders like SGS and JXSC Machine. - Gold Nugget Suction Pump: A DIY Tool for Efficient Gold Recovery

The Gold Nugget Suction Pump is a specialized suction device designed for gold prospectors to retrieve gold particles trapped in tight crevices, between rocks, or in hard-to-reach underwater areas. Built using everyday materials, this tool combines simplicity, durability, and precision to help you recover even the smallest gold flakes and nuggets. - The Essentials of Business Management and Accounting: Balancing Transparency and Trust

Within the critical landscape of business management, particularly for those venturing into ventures like initiating a gold mine operation, the necessity of robust accounting practices and open communication cannot be emphasized enough. This article explores the foundational elements required to maintain financial integrity and foster trust among all stakeholders involved in any business endeavor.

Within the critical landscape of business management, particularly for those venturing into ventures like initiating a gold mine operation, the necessity of robust accounting practices and open communication cannot be emphasized enough. This article explores the foundational elements required to maintain financial integrity and foster trust among all stakeholders involved in any business endeavor. - Profit-Sharing Model for Gold Mining Operations Utilizing Partner-Provided Sluices

This gold mining business model, through initial investment of $22,000, collaborates with local communities by providing essential equipment, charging a transparent fee, empowering miners with training, and offering premium gold purchase rates, while focusing on sustainability, minimizing environmental impact, promoting community development, and ensuring efficiency through low-cost operations and solar energy utilization.

This gold mining business model, through initial investment of $22,000, collaborates with local communities by providing essential equipment, charging a transparent fee, empowering miners with training, and offering premium gold purchase rates, while focusing on sustainability, minimizing environmental impact, promoting community development, and ensuring efficiency through low-cost operations and solar energy utilization. - How to Successfully Import Gold to India: A Guide by Jean Louis, Start Your Own Gold Mine

Importing gold to India is a lucrative yet highly regulated process that requires meticulous planning and adherence to legal frameworks. As someone who has worked extensively with clients in India, I, Jean Louis, founder of Start Your Own Gold Mine, can guide you through the essential steps—from obtaining the necessary licenses like the Import Export Code (IEC) to navigating customs duties and RBI regulations. Whether you’re an individual looking to import gold under baggage rules or a business aiming to work with authorized banks and agencies, this guide will help you understand the complexities of the process, avoid common pitfalls, and ensure compliance with Indian laws. Let’s turn your gold import aspirations into a seamless and profitable venture.

Importing gold to India is a lucrative yet highly regulated process that requires meticulous planning and adherence to legal frameworks. As someone who has worked extensively with clients in India, I, Jean Louis, founder of Start Your Own Gold Mine, can guide you through the essential steps—from obtaining the necessary licenses like the Import Export Code (IEC) to navigating customs duties and RBI regulations. Whether you’re an individual looking to import gold under baggage rules or a business aiming to work with authorized banks and agencies, this guide will help you understand the complexities of the process, avoid common pitfalls, and ensure compliance with Indian laws. Let’s turn your gold import aspirations into a seamless and profitable venture. - Exploring the World of Mineral Resources: Types, Importance, and Conservation

Mineral resources are the backbone of modern civilization, playing a critical role in almost every aspect of our daily lives. From the metals in our smartphones to the energy that powers our homes, mineral resources are indispensable. However, their extraction and use come with significant environmental and social challenges. This article provides an in-depth exploration of the types of mineral resources, their importance, the environmental impact of their extraction, and the urgent need for conservation. It also offers practical strategies for sustainable mineral use to ensure their availability for future generations.

Mineral resources are the backbone of modern civilization, playing a critical role in almost every aspect of our daily lives. From the metals in our smartphones to the energy that powers our homes, mineral resources are indispensable. However, their extraction and use come with significant environmental and social challenges. This article provides an in-depth exploration of the types of mineral resources, their importance, the environmental impact of their extraction, and the urgent need for conservation. It also offers practical strategies for sustainable mineral use to ensure their availability for future generations. - Heap Leaching vs. Carbon-in-Leach (CIL): A Comparison of Scalability, Efficiency, and Applications

Heap leaching and Carbon-in-Leach (CIL) are two widely used methods for extracting metals, particularly gold, from ores and tailings. While both processes aim to recover valuable metals, they differ significantly in terms of scalability, cost, efficiency, and suitability for different ore types. This article provides a detailed comparison of heap leaching and CIL, highlighting their advantages, limitations, and ideal applications, along with a summary table for quick reference. - Detailed Explanation of the SYOGM Gold Mine Production Line #1

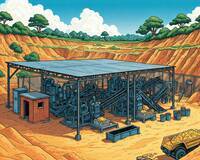

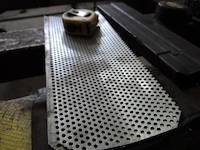

The proposed gold mine production line is designed for efficiency and cost-effectiveness in gold recovery, incorporating several key components. It begins with durable grizzly screens for rock classification, followed by a mechanical feeder that regulates the flow into a jaw crusher, which processes appropriately sized rocks. Oversized rocks are managed separately to prevent clogs, using manual methods to break them down, thus maintaining optimal production capacity. After the jaw crusher, smaller rock fragments are gravity-fed to impact mills for further pulverization, and a particle recirculation system, utilizing methods such as hydrocyclones or spiral concentrators, ensures larger particles are reprocessed for improved gold extraction. The finely milled material is then directed to sluices designed for fine gold recovery, leveraging gravitational flow for efficiency. This self-contained, gravity-fed production line minimizes transportation costs and time, ultimately enhancing productivity and profitability, validated by successful implementations in similar projects, thereby representing a reliable investment for sustainable gold mining operations. - Strategic Provisioning of Equipment to Village Miners in Exchange for Gold Benefits (Relationship Management)

This web page talks about a way for dealers and buyers to work together that is good for both sides. The dealers or buyers give miners in villages the equipment they need for mining gold. This helps the miners mine gold more efficiently. In return, the dealers and buyers get some of the profits from the gold-bearing rocks, or they get a good percentage of any precious metals that are found. They also get priority when buying these valuable resources and get discounts on future transactions. - We strive to bring customers to mining land, not the other way around

Start Your Own Gold Mine helps clients succeed by guiding them to proven, productive mining lands, avoiding common pitfalls of faulty exploration reports on potential mining properties. If a client's land does not appear to be profitable, our approach is reversed. Instead of bringing the client to a potentially infeasible mining site, we focus on finding suitable mining land that meets their needs, ensuring a more promising and successful mining venture.

Start Your Own Gold Mine helps clients succeed by guiding them to proven, productive mining lands, avoiding common pitfalls of faulty exploration reports on potential mining properties. If a client's land does not appear to be profitable, our approach is reversed. Instead of bringing the client to a potentially infeasible mining site, we focus on finding suitable mining land that meets their needs, ensuring a more promising and successful mining venture. - Step-by-step Guide for Effortless Commencement of Start Your Own Gold Mine Project in your country

This article provides a detailed budget and cost breakdown for starting your own gold mining project, explaining the process step-by-step.

This article provides a detailed budget and cost breakdown for starting your own gold mining project, explaining the process step-by-step. - Setting up Camp on a Gold Mining Site

This page provides guidance on setting up camp for small-scale gold prospecting. It emphasizes the importance of choosing a suitable location with potential for gold mining, followed by considerations for water and sanitation, protection from the elements, and equipment and tools needed for prospecting. Other essential aspects include hiring help, storage, communication and navigation, and keeping necessary administrative documents. The page emphasizes safety, sustainability, and environmental responsibility while encouraging readers to begin their own small-scale gold mining operation. - Understanding Potential for Alluvial Gold Mining Sites

To better understand the potential of alluvial gold mining sites, landlords and license holders should answer the following mining-related questions. - Mining License Compliance in East Africa

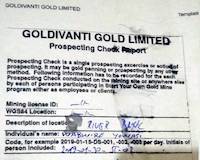

Mining license holders in East Africa frequently fail to comply with regulations, often more than 95% of the time, due to their lack of skilled personnel, instead hiring unqualified third parties to prepare reports, which are often inaccurate and do not adhere to international standards. The primary reason for this is the license holder's lack of executive education, which is essential for understanding their primary responsibility of achieving the organization's objectives by utilizing adequate organization and personnel. A professional executive is expected to oversee overall operations and strategic decision-making, while other essential professionals, such as accountants, secretaries, mining engineers, geologists, and skilled gold prospectors, are required to manage various aspects of the mining operation.

Mining license holders in East Africa frequently fail to comply with regulations, often more than 95% of the time, due to their lack of skilled personnel, instead hiring unqualified third parties to prepare reports, which are often inaccurate and do not adhere to international standards. The primary reason for this is the license holder's lack of executive education, which is essential for understanding their primary responsibility of achieving the organization's objectives by utilizing adequate organization and personnel. A professional executive is expected to oversee overall operations and strategic decision-making, while other essential professionals, such as accountants, secretaries, mining engineers, geologists, and skilled gold prospectors, are required to manage various aspects of the mining operation. - How to differentiate between alluvial and eluvial gold nuggets

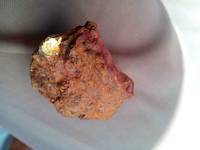

By observing the shape, surface texture, and color of the gold nugget, you can determine whether it is alluvial or eluvial. Keep in mind that the shape and appearance of gold nuggets can vary significantly, so experience and knowledge of the local gold-bearing area can be helpful in making an accurate identification. - Detailed Explanation of the SYOGM Gold Mine Production Line #0

The SYOGM Gold Mine Production Line #1 is a basic hard rock production line that may be used before more serious stage of work during prospecting and initial days of the work. - Opportunities in Gold Mining with a Modest $8,000 Investment

Starting a gold mining operation with a modest $8,000 investment, involving setup, equipment, and production stages to yield a potentially lucrative return. This specific strategic approach is distinct from traditional gold prospecting methods, where the focus is typically on searching for gold deposits in unexplored territories. Instead, we adopt a more targeted and efficient strategy, where we visit existing sites that have been previously mined or explored, and process their tailings, rocks, and gold-bearing ores.

Starting a gold mining operation with a modest $8,000 investment, involving setup, equipment, and production stages to yield a potentially lucrative return. This specific strategic approach is distinct from traditional gold prospecting methods, where the focus is typically on searching for gold deposits in unexplored territories. Instead, we adopt a more targeted and efficient strategy, where we visit existing sites that have been previously mined or explored, and process their tailings, rocks, and gold-bearing ores. - Importance of Representative Sample

A representative sample for gold grade is a meticulously collected and processed portion of ore that accurately reflects the average gold concentration of the entire mineral deposit. This sample is essential for determining the true value and potential profitability of a gold mining operation. To ensure its representativeness, the sampling process must follow standardized protocols, including proper sampling techniques, adequate sample size, and uniform distribution across different sections of the deposit. Additionally, the sample should undergo rigorous testing and analysis in a controlled laboratory environment to provide reliable and consistent gold grade measurements. By obtaining a representative sample, mining professionals can make informed decisions regarding extraction methods, resource estimation, and economic feasibility, ultimately enhancing the efficiency and success of gold recovery efforts.

A representative sample for gold grade is a meticulously collected and processed portion of ore that accurately reflects the average gold concentration of the entire mineral deposit. This sample is essential for determining the true value and potential profitability of a gold mining operation. To ensure its representativeness, the sampling process must follow standardized protocols, including proper sampling techniques, adequate sample size, and uniform distribution across different sections of the deposit. Additionally, the sample should undergo rigorous testing and analysis in a controlled laboratory environment to provide reliable and consistent gold grade measurements. By obtaining a representative sample, mining professionals can make informed decisions regarding extraction methods, resource estimation, and economic feasibility, ultimately enhancing the efficiency and success of gold recovery efforts. - Introduction to Mineral Processing in East Africa

Start Your Own Gold Mine provides comprehensive turnkey services to establish gold mineral processing operations in East Africa, encompassing land acquisition, equipment installation, staff training, and regulatory compliance.

Start Your Own Gold Mine provides comprehensive turnkey services to establish gold mineral processing operations in East Africa, encompassing land acquisition, equipment installation, staff training, and regulatory compliance. - Categories of Available Gold for Trade and Export

At Start Your Own Gold Mine, we collaborate with genuine and licensed gold dealers across East Africa to offer a diverse range of gold categories available for purchase in Uganda, Kenya, and Tanzania. These categories cater to various investment needs and preferences, ensuring that our clients can find the perfect gold type to suit their trading and export requirements.

At Start Your Own Gold Mine, we collaborate with genuine and licensed gold dealers across East Africa to offer a diverse range of gold categories available for purchase in Uganda, Kenya, and Tanzania. These categories cater to various investment needs and preferences, ensuring that our clients can find the perfect gold type to suit their trading and export requirements.

- Review of geological reports for compliance with NI 43-101

The uploaded document, titled "NI43-101 Technical Geological Report for Limani Gold Prospect," outlines geological, environmental, and operational aspects of a mining project. However, compliance with NI 43-101, a Canadian standard for the disclosure of mineral project information, is stringent and requires adherence to specific content and reporting guidelines. - Best Practices After Obtaining a Mining and Exploration License for Over 100 km²

Once you've secured a mining and exploration license for an area exceeding 100 km², the journey towards successful gold mining begins. This comprehensive guide outlines the most effective steps to take, ensuring a strategic and efficient approach to your mining endeavors. - Unlock Gold Success with Kassanda Rapid Rock Verification!

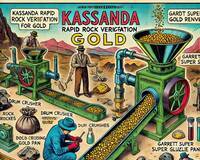

Introducing the game-changer: Kassanda Rapid Rock Verification for Gold! 🚀 Developed by Louis himself, this innovative field assaying method allows you to quickly and accurately assess gold content in rocks right on-site. Say goodbye to long waits and hello to efficient, reliable results! ⏱️💰

Introducing the game-changer: Kassanda Rapid Rock Verification for Gold! 🚀 Developed by Louis himself, this innovative field assaying method allows you to quickly and accurately assess gold content in rocks right on-site. Say goodbye to long waits and hello to efficient, reliable results! ⏱️💰 - Visiting Uganda for a Mining Site Tour: Insights and Practical Tips

Uganda, renowned for its rich mineral deposits, offers a unique opportunity for aspiring miners and industry professionals to explore its vibrant mining sector. Whether you're an investor, a mining enthusiast, or part of a team planning a site visit, understanding the local landscape and cultural nuances is crucial for a successful and safe experience. Jean M. Louis, a seasoned mentor from the Start Your Own Gold Mine program, shares invaluable insights to help you navigate your mining site visit in Uganda effectively.

Uganda, renowned for its rich mineral deposits, offers a unique opportunity for aspiring miners and industry professionals to explore its vibrant mining sector. Whether you're an investor, a mining enthusiast, or part of a team planning a site visit, understanding the local landscape and cultural nuances is crucial for a successful and safe experience. Jean M. Louis, a seasoned mentor from the Start Your Own Gold Mine program, shares invaluable insights to help you navigate your mining site visit in Uganda effectively. - Discover the Future of Gold Mining with SYOGM Advance Wash Plant!

Are you ready to take your gold mining operation to the next level? Introducing the **SYOGM Advance Wash Plant**, a game-changer in gold recovery systems! Designed and perfected in the stunning landscapes of **Uganda**, this innovative wash plant will revolutionize the way you extract gold. And the best part? We deliver **worldwide!** 🌟

Are you ready to take your gold mining operation to the next level? Introducing the **SYOGM Advance Wash Plant**, a game-changer in gold recovery systems! Designed and perfected in the stunning landscapes of **Uganda**, this innovative wash plant will revolutionize the way you extract gold. And the best part? We deliver **worldwide!** 🌟 - Terms and Conditions for Gold Mining Equipment Manufacturing by Start Your Own Gold Mine

Start Your Own Gold Mine offers comprehensive terms and conditions governing the manufacture, sale, and use of specialized gold mining equipment.

Start Your Own Gold Mine offers comprehensive terms and conditions governing the manufacture, sale, and use of specialized gold mining equipment. - Report of prospecting on land of professor Magezi Kirigwajjo from 26 October 2024

- Salting of Mining Lands

Salting refers to the deceptive practice of artificially enhancing the perceived value of mining lands by introducing or indicating the presence of valuable minerals, such as gold, that are not actually present in commercially viable quantities. This fraudulent activity can lead to substantial financial losses for inexperienced investors who may not have the means to verify the actual conditions of the land before committing resources. Salting can take many forms, including the placement of small amounts of gold in visible locations or misleading claims about the richness of a property based on manipulated measurements.

Salting refers to the deceptive practice of artificially enhancing the perceived value of mining lands by introducing or indicating the presence of valuable minerals, such as gold, that are not actually present in commercially viable quantities. This fraudulent activity can lead to substantial financial losses for inexperienced investors who may not have the means to verify the actual conditions of the land before committing resources. Salting can take many forms, including the placement of small amounts of gold in visible locations or misleading claims about the richness of a property based on manipulated measurements. - Comprehensive Control and Management of the Gold Mining Company

An all-encompassing framework for the effective oversight, strategic direction, and operational administration of a gold mining company, ensuring optimal resource utilization, regulatory compliance, and sustainable growth in a competitive market. - Start Your Own Gold Mine headquarter and branches

"Launch your gold mining venture with Start Your Own Gold Mine, featuring headquarters and branches across East Africa." - I want to produce 20-25 kilos a month, how much should I invest?

This article provides a comprehensive guide on the startup costs and essential considerations for investing in gold mining in Uganda, specifically targeting a production goal of 20-25 kilograms per month.

This article provides a comprehensive guide on the startup costs and essential considerations for investing in gold mining in Uganda, specifically targeting a production goal of 20-25 kilograms per month. - Buying and selling gold in Uganda, Tanzania and Kenya

In order to successfully navigate the gold trade industry in East Africa's Uganda, Tanzania, and Kenya, newcomers should prioritize a comprehensive understanding of market dynamics, exercise due diligence, and acquire straightforward market knowledge. This will not only enhance their chances of success but also minimize potential risks and maximize opportunities in this lucrative sector.

In order to successfully navigate the gold trade industry in East Africa's Uganda, Tanzania, and Kenya, newcomers should prioritize a comprehensive understanding of market dynamics, exercise due diligence, and acquire straightforward market knowledge. This will not only enhance their chances of success but also minimize potential risks and maximize opportunities in this lucrative sector. - Step-by-step Guide for Effortless Commencement of Start Your Own Gold Mine Project in your country

In the quest for gold in a gold-rich area, the discovery of the initial gold deposit is a crucial step in generating income. With expert guidance and support, a comprehensive mining site plan is developed, and the client's team is trained and equipped to efficiently extract gold. Our consulting fee is $6,000 per month, with the potential for further savings through manufacturing their own machines. For alluvial gold mining, processing costs can be significantly reduced. The journey from initial discovery to establishing a full-fledged gold mine can take 45 days or less, with our expertise ensuring success and sustainability.

In the quest for gold in a gold-rich area, the discovery of the initial gold deposit is a crucial step in generating income. With expert guidance and support, a comprehensive mining site plan is developed, and the client's team is trained and equipped to efficiently extract gold. Our consulting fee is $6,000 per month, with the potential for further savings through manufacturing their own machines. For alluvial gold mining, processing costs can be significantly reduced. The journey from initial discovery to establishing a full-fledged gold mine can take 45 days or less, with our expertise ensuring success and sustainability. - Start Your Own Gold Mine in 45 days with US $22,000

The Start Your Own Gold Mine program for the consulting fee of US $22,000 provides a client with a full bundle of previously created and prepared resources so that first 5 kilograms of gold may be produced and shared between the client and our company by the ratio of 3 kilograms for client and 2 kilograms for our company. Upon completion of full training and production of 5 kilograms of gold, business remains to client for the future. Clients are expected to have more available capital then the fee that is paid in Start Your Own Gold Mine for their expenses of accommodation or residency expenses. - Countries available to Start Your Own Gold Mine

Our group have legal establishments in Rwanda, Uganda, Kenya and Tanzania. We may potentially work in any of the East African countries such as Burundi, South Sudan but also the Democratic Republic of Congo. In addition, the Start Your Own Gold Mine program can be executed in other countries around the world where legal mining is possible. Our team has extensive experience in training staff members and can provide assistance in sending our staff members to different countries to support the implementation of the program. - Investors seeking Explored Lands With Reports in East Africa

Foreign investors often inquire with us about lands that come with comprehensive reports, meeting specific standards. They seek certainty in terms of the quality and validity of these reports, as they form the basis of their investment assessments. Unfortunately, the existing reports in many East African countries do not always meet these standard requirements. This lack of consistency in reporting quality poses a challenge for foreign investors who rely on such reports to evaluate the potential of gold mining projects and minimize risks.

Foreign investors often inquire with us about lands that come with comprehensive reports, meeting specific standards. They seek certainty in terms of the quality and validity of these reports, as they form the basis of their investment assessments. Unfortunately, the existing reports in many East African countries do not always meet these standard requirements. This lack of consistency in reporting quality poses a challenge for foreign investors who rely on such reports to evaluate the potential of gold mining projects and minimize risks.

- Where and How to Buy Anonymously Gold for Cash in Europe?

In this article, we will explore how to purchase gold anonymously for cash in Europe without revealing which country is the best for this purpose. - The Gold Trade in East Africa: Understanding the Market and Approach

The gold trade in East Africa is booming, with ample opportunities for business deals. However, foreign traders often struggle to navigate the market due to differences in mentality and approach. In this article, we will explore the key factors that gold traders need to understand in order to succeed in this region.

The gold trade in East Africa is booming, with ample opportunities for business deals. However, foreign traders often struggle to navigate the market due to differences in mentality and approach. In this article, we will explore the key factors that gold traders need to understand in order to succeed in this region. - Executive Summary to Start Your Own Gold Mine with Mineral Processing in Uganda

The Executive Summary serves as a business proposal for clients who wish to Start Your Own Gold Mine through a well-researched and experienced business opportunity in mineral processing. The proposed mineral processing venture is sustainable and scalable, leveraging extensive knowledge and experience gained since 2012. The market opportunity is significant due to the large number of miners in the districts of Uganda and the lack of professional and efficient mineral processing centers currently serving the miners. By occupying this market with our low-risk and targeted strategy, clients position themselves to become the leading provider of mineral processing services in the region, offering to investors a lucrative income-generating opportunity. - SYOGM Advance Gold Wash Plant Design

The SYOGM (Start Your Own Gold Mine) Advance Wash Plant is an innovative gold recovery system that allows miners to efficiently and effectively extract gold particles from dirt. The wash plant design incorporates various components and processes to ensure optimal extraction and recovery of gold.

The SYOGM (Start Your Own Gold Mine) Advance Wash Plant is an innovative gold recovery system that allows miners to efficiently and effectively extract gold particles from dirt. The wash plant design incorporates various components and processes to ensure optimal extraction and recovery of gold. - Easiest-to-use washplant for excavator applications

* Captured Region Text Buffer name: *RCD TEMPORARY BUFFER* Buffer file: /home/data1/protected/tmp/2024-01-12-19:45:22-RCD TEMPORARY BUFFER.txt Time captured: 2024-01-13-20:15:57 - Exploring the Economic Potential of Gold Mining in Mubende District and Kassanda, Uganda

* Captured Region Text Buffer name: *RCD TEMPORARY BUFFER* Buffer file: /home/data1/protected/tmp/2024-01-08-20:56:10-RCD TEMPORARY BUFFER.txt Time captured: 2024-01-09-11:42:28 - Resumen Ejecutivo sobre Procesamiento de Minerales por Start Your Own Gold Mine

El Resumen Ejecutivo sirve como una propuesta de negocio para asociarse con inversionistas en busca de una oportunidad de negocio bien investigada y con experiencia. La propuesta de empresa de procesamiento de minerales es sostenible y escalable, aprovechando el extenso conocimiento y experiencia adquiridos desde 2012. La oportunidad del mercado es significativa debido al gran número de mineros en los distritos de Uganda y a la falta de centros de procesamiento de minerales profesionales y eficientes que actualmente sirvan a los mineros. Al ocupar este mercado con nuestra estrategia de bajo riesgo y enfocada, nos posicionamos para convertirnos en el principal proveedor de servicios de procesamiento de minerales en la región, ofreciendo a los inversionistas una lucrativa oportunidad de generar ingresos. - Mineral Rights vs. Gold Mines: Exploring the Differences

In the world of mining and exploration, there are two key terms that often cause confusion: mineral rights and gold mines. While both are related to the extraction of valuable resources from the earth, they refer to distinct aspects of the industry. - Factors Affecting Gold Recovery in Cyanidation in East African Countries

The efficiency of gold recovery in artisanal cyanidation in East Africa is influenced by factors such as gold particle size, mineralogy of the ore or tailings, presence of cyanide-consuming compounds, cyanide concentration and contact time, and pH level of the leach solution.

The efficiency of gold recovery in artisanal cyanidation in East Africa is influenced by factors such as gold particle size, mineralogy of the ore or tailings, presence of cyanide-consuming compounds, cyanide concentration and contact time, and pH level of the leach solution. - Rivendosja artizanale e arit në Lindjen e Afrikës.

Përshkrim i hollësishëm i rimëkëmbjes së artezanale të arit në Afrikën Lindore, përfshirë planifikimin e minierave, zbatimin e masave të sigurisë, nxjerrjen dhe hoqjen e mineralave, transportimin efikas të mineraleve, shthurjen dhe grirjen e materialeve të papërpunuara, ndarjen e arit nga mineralet e tjera, përpunimin e koncentratit përfundimtar, përmirësimin e pastërimit dhe shndërrimin e koncentratit në metal të rafinuar për shitje.

Përshkrim i hollësishëm i rimëkëmbjes së artezanale të arit në Afrikën Lindore, përfshirë planifikimin e minierave, zbatimin e masave të sigurisë, nxjerrjen dhe hoqjen e mineralave, transportimin efikas të mineraleve, shthurjen dhe grirjen e materialeve të papërpunuara, ndarjen e arit nga mineralet e tjera, përpunimin e koncentratit përfundimtar, përmirësimin e pastërimit dhe shndërrimin e koncentratit në metal të rafinuar për shitje. - Artisanal Gold Recovery in East Africa

Elaborated description of artisanal gold recovery in East Africa, involving mine planning, implementing safety measures, excavating and removing ores, efficiently transporting minerals, crushing and milling raw materials, separating gold from other minerals, processing final concentrate, enhancing purity, and converting concentrate into refined metal for sales.

Elaborated description of artisanal gold recovery in East Africa, involving mine planning, implementing safety measures, excavating and removing ores, efficiently transporting minerals, crushing and milling raw materials, separating gold from other minerals, processing final concentrate, enhancing purity, and converting concentrate into refined metal for sales. - Executive Summary für Mineralverarbeitung durch Start Your Own Gold Mine

Die Executive Summary dient als Geschäftsvorschlag für eine Partnerschaft mit Investoren, die eine fundierte und erfahrene Geschäftsmöglichkeit suchen. Das vorgeschlagene Mineralverarbeitungsunternehmen ist nachhaltig und skalierbar und profitiert von umfangreichem Wissen und Erfahrung, die seit 2012 gesammelt wurden. Die Marktchancen sind signifikant aufgrund der großen Anzahl von Minenarbeitern in den Distrikten in Uganda und dem Mangel an professionellen und effizienten Mineralverarbeitungszentren, die derzeit die Bergleute bedienen. Durch die Besetzung dieses Marktes mit unserer risikoarmen und zielgerichteten Strategie positionieren wir uns als führender Anbieter von Mineralverarbeitungsdienstleistungen in der Region und bieten Investoren eine lukrative Einkommensmöglichkeit. - Izvršni sažetak o obradi minerala od strane Start Your Own Gold Mine

Izvršni sažetak služi kao poslovna ponuda za partnerstvo s investitorima koji traže dobro istraženu i iskusnu poslovnu priliku. Predloženi posao obrade minerala je održiv i razmjeran, temeljen na opsežnom znanju i iskustvu stečenom od 2012. godine. Prilika na tržištu je značajna zbog velikog broja rudara u okruzima Ugande i nedostatka profesionalnih i učinkovitih centara za obradu minerala koji trenutno pružaju usluge rudarima. Zauzimajući ovo tržište s našom niskorizičnom i ciljanom strategijom, pozicioniramo se kao vodeći pružatelj usluga obrade minerala u regiji, nudeći investitorima unosnu mogućnost generiranja prihoda. - Small-Scale Mineral Processing: Unlocking Potential and Ensuring Sustainable Gold Recovery

The mineral processing of the mother lode presents a promising opportunity for small-scale operations in Uganda. This article explores the various stages and processes involved in extracting gold from prospecting rocks to the final recovery, while highlighting the commitment to environmentally friendly practices. - RIASSUNTO ESECUTIVO SULLA LAVORAZIONE DI MINERALI DA START YOUR OWN GOLD MINE IN UGANDA

The Executive Summary serves as a business proposal for partnership with investors seeking a well-researched and experienced business opportunity. The proposed mineral processing venture is sustainable and scalable, leveraging extensive knowledge and experience gained since 2012. The market opportunity is significant due to the large number of miners in the districts of Uganda and the lack of professional and efficient mineral processing centers currently serving the miners. By occupying this market with our low-risk and targeted strategy, we position ourselves to become the leading provider of mineral processing services in the region, offering investors a lucrative income-generating opportunity. - Financing of Gold Mining Site That Lacks Proper Business Management, Administration, And Record-Keeping

These sites are already producing gold but require financial and investment support to improve their operations and maximize profitability. For this stage of development, we focus on mining sites that are already producing gold but lack proper business management, administration, and record-keeping. Our aim is to provide financing and investment opportunities for these sites under specific conditions.

These sites are already producing gold but require financial and investment support to improve their operations and maximize profitability. For this stage of development, we focus on mining sites that are already producing gold but lack proper business management, administration, and record-keeping. Our aim is to provide financing and investment opportunities for these sites under specific conditions. - Securing Capital for Mining Lands with Presumed Gold Deposits

We are excited to present our service for the development of gold mining land. Our company, Start Your Own Gold Mine, specializes in prospecting and exploration services for plain land assumed to have minerals. This land has no previous production and no neighboring production.

We are excited to present our service for the development of gold mining land. Our company, Start Your Own Gold Mine, specializes in prospecting and exploration services for plain land assumed to have minerals. This land has no previous production and no neighboring production. - Funding for Gold Mining Site Development

Are you in search of funding opportunities for the development of gold mining sites? Look no further. Start Your Own Gold Mine has been providing financial support for mining projects since 2011. We have successfully funded the growth and establishment of numerous mining sites across Tanzania, Uganda, and Kenya. - Improving Gold Recovery from Artisanal Tailings in East Africa

This page discusses methods to improve gold recovery from artisanal tailings in East Africa. It provides an overview of the challenges faced by village miners and outlines a procedure for starting a gold recovery business in Uganda, Tanzania, and Kenya.

This page discusses methods to improve gold recovery from artisanal tailings in East Africa. It provides an overview of the challenges faced by village miners and outlines a procedure for starting a gold recovery business in Uganda, Tanzania, and Kenya. - Gold Recovery: Chlorination Leaching of Tailings

Discover the process of extracting gold from tailings through chlorination leaching, including the necessary steps, safety considerations, and effective techniques for maximizing gold recovery. - DIY Activated Carbon - Acid Activation in East Africa

The article provides a simplified procedure for making activated carbon using acid activation, emphasizing the steps involved and the materials needed. - How To Prepare Analysis Of Copper Ores For Seller Evaluation

Guide to Preparing Copper Ore Analysis for Seller Evaluation: Learn the step-by-step process of analyzing copper ores, including chemical analysis, assay techniques, physical properties, and mineralogical analysis, to present comprehensive data for evaluation by potential sellers. - Executive Summary on Mineral Processing by Start Your Own Gold Mine

The Executive Summary serves as a business proposal for partnership with investors seeking a well-researched and experienced business opportunity. The proposed mineral processing venture is sustainable and scalable, leveraging extensive knowledge and experience gained since 2012. The market opportunity is significant due to the large number of miners in the districts of Uganda and the lack of professional and efficient mineral processing centers currently serving the miners. By occupying this market with our low-risk and targeted strategy, we position ourselves to become the leading provider of mineral processing services in the region, offering investors a lucrative income-generating opportunity. - 1 acre, gold mining site in Uganda, sale for 5% of $2,000,000 value

We are excited to present an extraordinary investment opportunity—1 acre of prime gold mining land in Uganda. This lucrative gold mining site is now available for sale at a fantastic value of only 5% of its estimated total worth of $2,000,000.

We are excited to present an extraordinary investment opportunity—1 acre of prime gold mining land in Uganda. This lucrative gold mining site is now available for sale at a fantastic value of only 5% of its estimated total worth of $2,000,000. - ✨ Introducing our Gold Refining System! 💰

Introducing our Gold Refining System: With our fully self-contained and safe system, you can hassle-free refine 1-2 kg of gold per day. No fumes, no worries! We provide full training to ensure you have the necessary skills to operate the system with confidence. Our worldwide deliveries make it easy for you to start refining gold and exporting it yourself, especially in countries like Uganda where only refined gold can be exported. Take control of your gold production today! For larger systems capable of refining 30-50 kg per day, please contact us for further details.

Introducing our Gold Refining System: With our fully self-contained and safe system, you can hassle-free refine 1-2 kg of gold per day. No fumes, no worries! We provide full training to ensure you have the necessary skills to operate the system with confidence. Our worldwide deliveries make it easy for you to start refining gold and exporting it yourself, especially in countries like Uganda where only refined gold can be exported. Take control of your gold production today! For larger systems capable of refining 30-50 kg per day, please contact us for further details. - Preliminary Site Inspection and Assessment

Discover the power of our Preliminary Site Assessment and Inspection service! Led by mining expert Mr. Jean Louis, our team conducts comprehensive evaluations of mining sites in Tanzania, Uganda, and other Start Your Own Gold Mine program locations. 🌍🔎 From assessing living and working resources to analyzing previous gold mining activities and determining future development potential, we provide valuable insights to help you make informed decisions. 💼⛏️ Ensure the success and profitability of your mining venture with our expert assessment. Contact us today to schedule your assessment and embark on the path to gold mining success! ✨🚀 - PIZZA RULE FOR GOLD DEALS IN UGANDA, LCO POLICY LETTER OF 9 OCTOBER 2023

The "Pizza Rule" implemented by Jean Louis and his company in Kampala aims to address unreliable prospects in the gold trade by requiring a symbolic gesture of commitment. Prospective businesspersons who fail to honor a scheduled meeting or bring even a single gram of gold for purchase must send an amount equivalent to 120,000 Ugandan shillings (approximately US $35) as compensation for any inconvenience caused. Additionally, local sellers must bring at least 10 grams of gold to the office to proceed. This rule, inspired by European business practices involving lunch meetings, ensures that only serious and committed individuals engage in business dealings, thereby streamlining the gold procurement process and minimizing wasted time and resources.

The "Pizza Rule" implemented by Jean Louis and his company in Kampala aims to address unreliable prospects in the gold trade by requiring a symbolic gesture of commitment. Prospective businesspersons who fail to honor a scheduled meeting or bring even a single gram of gold for purchase must send an amount equivalent to 120,000 Ugandan shillings (approximately US $35) as compensation for any inconvenience caused. Additionally, local sellers must bring at least 10 grams of gold to the office to proceed. This rule, inspired by European business practices involving lunch meetings, ensures that only serious and committed individuals engage in business dealings, thereby streamlining the gold procurement process and minimizing wasted time and resources. - Willkommen bei Start Your Own Gold Mine

Willkommen bei Start Your Own Gold Mine! Wir sind Experten für die Feingoldgewinnung und bieten effiziente Dienstleistungen an, um die Produktivität beim Goldbergbau zu maximieren und die Kosten zu minimieren. Mit über 350+ Bergbaustandorten weltweit sind wir Ihr zuverlässiger Partner für den Goldabbau. Kontaktieren Sie uns für Investitionsmöglichkeiten und weitere Informationen! - Financing of Gold Mining Projects

The article delves into the investment focus of Start Your Own Gold Mine, a company that specializes in investing in productive gold mines that already have a certain level of gold production. The company avoids investing in gold prospecting, as it is considered a service rather than a productive mine.

The article delves into the investment focus of Start Your Own Gold Mine, a company that specializes in investing in productive gold mines that already have a certain level of gold production. The company avoids investing in gold prospecting, as it is considered a service rather than a productive mine. - Gold Mining and Prospecting Glossary in Start Your Own Gold Mine program

Welcome to the Start Your Own Gold Mine program! Our website features a comprehensive glossary of terms related to gold mining and prospecting. Whether you are a beginner or an experienced miner, our glossary is designed to provide you with a valuable resource to enhance your knowledge and understanding of the industry. From basic terminology to advanced concepts, our carefully curated glossary covers everything you need to know about gold mining, including terms like placer mining, lode deposit, dredging, panning, and much more. Whether you are looking to embark on your own gold mining venture or simply want to expand your knowledge, our glossary is your go-to reference. Start exploring today and unlock the secrets of gold mining and prospecting with Start Your Own Gold Mine!

Welcome to the Start Your Own Gold Mine program! Our website features a comprehensive glossary of terms related to gold mining and prospecting. Whether you are a beginner or an experienced miner, our glossary is designed to provide you with a valuable resource to enhance your knowledge and understanding of the industry. From basic terminology to advanced concepts, our carefully curated glossary covers everything you need to know about gold mining, including terms like placer mining, lode deposit, dredging, panning, and much more. Whether you are looking to embark on your own gold mining venture or simply want to expand your knowledge, our glossary is your go-to reference. Start exploring today and unlock the secrets of gold mining and prospecting with Start Your Own Gold Mine! - How to Start Your Own Gold Mine?

Start Your Own Gold Mine is your trusted partner in starting and managing a successful gold mining operation. With our comprehensive support and expertise, we guide you through every step of the process, from research and exploration to obtaining permits and setting up infrastructure. Our team of experienced professionals is dedicated to helping you achieve your goals in the gold mining industry. Visit our website to learn more about the services we offer and how we can assist you in starting your own profitable gold mine.

Start Your Own Gold Mine is your trusted partner in starting and managing a successful gold mining operation. With our comprehensive support and expertise, we guide you through every step of the process, from research and exploration to obtaining permits and setting up infrastructure. Our team of experienced professionals is dedicated to helping you achieve your goals in the gold mining industry. Visit our website to learn more about the services we offer and how we can assist you in starting your own profitable gold mine. - Importance of Core Drilling in Mining

At Start Your Own Gold Mine, we understand the importance of core drilling in mining operations. We are dedicated to providing high-quality and affordable services to our clients in East Africa. For 30 meter deep core drilling, we offer the most affordable services in all of East Africa, guaranteed. Our expert team, state-of-the-art equipment, and commitment to safety and efficiency make us the ideal choice for your core drilling needs.

At Start Your Own Gold Mine, we understand the importance of core drilling in mining operations. We are dedicated to providing high-quality and affordable services to our clients in East Africa. For 30 meter deep core drilling, we offer the most affordable services in all of East Africa, guaranteed. Our expert team, state-of-the-art equipment, and commitment to safety and efficiency make us the ideal choice for your core drilling needs. - Financial Breakdown for Small-Scale Mining Company

This page provides a concise financial breakdown for a small-scale mining company involved in rock mining and shaft sinking. It highlights the key categories and expenses involved in the financial operations of such a business. Please note that the breakdown presented here is a general overview and should be tailored to suit the specific circumstances and requirements of the mining company. Consulting with financial professionals and conducting a comprehensive analysis is recommended for a more precise financial assessment.

This page provides a concise financial breakdown for a small-scale mining company involved in rock mining and shaft sinking. It highlights the key categories and expenses involved in the financial operations of such a business. Please note that the breakdown presented here is a general overview and should be tailored to suit the specific circumstances and requirements of the mining company. Consulting with financial professionals and conducting a comprehensive analysis is recommended for a more precise financial assessment. - Gold concentration method by tapping during gold panning

Tapping is one of many of methods used during the gold panning process. Gold concentration method by tapping concentrates even the invisible gold to the side of the gold pan. Tapping goes hand in hand with backwashing of the blacksand. Gold panner may efficiently remove the black sand by tapping, concentrating gold at the top of the gold pan, and backwashing the blacksand away from the gold.

Tapping is one of many of methods used during the gold panning process. Gold concentration method by tapping concentrates even the invisible gold to the side of the gold pan. Tapping goes hand in hand with backwashing of the blacksand. Gold panner may efficiently remove the black sand by tapping, concentrating gold at the top of the gold pan, and backwashing the blacksand away from the gold. - KASSANDA RAPID ROCK VERIFICATION FOR GOLD, LCO BULLETIN OF 26 APRIL 2023

- Facts On How to Start Your Own Gold Mine

- 2023-03-29 Gold panning procedure for mother lode gold after processing with the rock impact mill

This is the gold panning procedure to verify for the gold from mother lode rocks, immediately after crushing of few buckets by using the SYOGM Rock Impact Mill. Watch the video and keep using this processs. If process takes longer than 3 minutes, you are doing something wrong.

This is the gold panning procedure to verify for the gold from mother lode rocks, immediately after crushing of few buckets by using the SYOGM Rock Impact Mill. Watch the video and keep using this processs. If process takes longer than 3 minutes, you are doing something wrong. - Gold Mining Lands For Sale and Partnership

Our business helps clients to Start Your Own Gold Mine. Since 2012 we have been in continuous contact with gold mining lands and mining sites, or claims and their license holders in East Africa and other countries. On many of these lands we have already conducted Preliminary Site Inspection and Assessment. Majority of these gold mining lands may be made ready for gold production after only one month of exploration and prospecting service Matrix Gold Prospecting. We recommend start of gold production only after identification of gold bearing deposits on such lands.

Our business helps clients to Start Your Own Gold Mine. Since 2012 we have been in continuous contact with gold mining lands and mining sites, or claims and their license holders in East Africa and other countries. On many of these lands we have already conducted Preliminary Site Inspection and Assessment. Majority of these gold mining lands may be made ready for gold production after only one month of exploration and prospecting service Matrix Gold Prospecting. We recommend start of gold production only after identification of gold bearing deposits on such lands. - POLICY ON PRACTICAL COORDINATION, LCO POLICY LETTER OF 6 JULY 2022

This policy outlines practical coordination requirements for executing plans, programs, projects, and tasks in both close and distant interactions within LOUIS Communication Office. It emphasizes the importance of documenting instructions in writing, thoroughly understanding them before responding to supervisors with detailed confirmations or communications regarding progress or obstacles encountered during execution. Coordination involves communicating intentions beforehand, updating on progress throughout implementation, and reporting completion details afterward. - SYOGM Rock Impact Mill

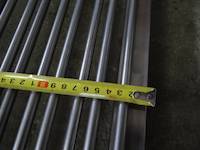

SYOGM Rock Impact Mill refers to low-cost, highly efficient, crushing and grinding impact mill with capacity of 500 kg and even up to 900 kg per hour. Capacity depends of the operator's skills and speed of work. This type of rock impact mill can easily replace rudimentary and very expensive ball mills such as those used in East Africa, in Tanzania, Uganda or Kenya or neighboring countries. While local village miners need to dry their rocks, this rock impact mill will work with water and without drying. It may process dry rocks as well. The machine may be transported by 2 people from a car to operating site. Or it may be transported by one person and wheelbarrow. Thus it is very mobile. Recovery screen is 1 mm and may be adjusted. We know from practical testing and scientific journal that screen of 1.5 mm is good enough to achieve almost optimum recovery. Thus our screen of 1 mm is more than enough to provide optimum recovery for small scale miners in East Africa and in other countries. This is pass-through grinding machine. It means that it may be used for very quick gold discovery and field sampling.

SYOGM Rock Impact Mill refers to low-cost, highly efficient, crushing and grinding impact mill with capacity of 500 kg and even up to 900 kg per hour. Capacity depends of the operator's skills and speed of work. This type of rock impact mill can easily replace rudimentary and very expensive ball mills such as those used in East Africa, in Tanzania, Uganda or Kenya or neighboring countries. While local village miners need to dry their rocks, this rock impact mill will work with water and without drying. It may process dry rocks as well. The machine may be transported by 2 people from a car to operating site. Or it may be transported by one person and wheelbarrow. Thus it is very mobile. Recovery screen is 1 mm and may be adjusted. We know from practical testing and scientific journal that screen of 1.5 mm is good enough to achieve almost optimum recovery. Thus our screen of 1 mm is more than enough to provide optimum recovery for small scale miners in East Africa and in other countries. This is pass-through grinding machine. It means that it may be used for very quick gold discovery and field sampling. - Ispiranje zlata u Hrvatskoj, Nenad Šerepec

Ispirač zlata u Hrvatskoj i proizvođač opreme za ispiranje zlata dokazao se na više lokacija kao na rijeci Dravi, onda na Bilogori i na raznim drugim lokacijama. Nenad Šerepec, bolestan od zlatne groznice, ispirač zlata u Hrvatskoj.

Ispirač zlata u Hrvatskoj i proizvođač opreme za ispiranje zlata dokazao se na više lokacija kao na rijeci Dravi, onda na Bilogori i na raznim drugim lokacijama. Nenad Šerepec, bolestan od zlatne groznice, ispirač zlata u Hrvatskoj. - If you can catch a leprechaun...

A leprechaun, according to Irish legend is a dwarf who keeps a pot of gold hidden away. If you can catch a leprechaun, your troubles are over. Because he keeps his gold just for ransom money. If you catch him, he'll quickly tell you where his gold is, so you'll let him go.

A leprechaun, according to Irish legend is a dwarf who keeps a pot of gold hidden away. If you can catch a leprechaun, your troubles are over. Because he keeps his gold just for ransom money. If you catch him, he'll quickly tell you where his gold is, so you'll let him go. - When people inquire with us "having buyers" that we may send them gold...

This page is short description how having buyers does not really help those companies in East Africa. Gold buyers are just everywhere, we have buyers who pay good prices. Especially companies which accumulate gold in stock never lack a gold buyer. To provide some gold production we would need to have some benefits. - 2020-05-04: Mzungu shoes

Sandals are best to be worn in such area.

Sandals are best to be worn in such area. - 2020-05-04: Camp life at gold mining site

That is how camp life at gold mining site looks like. There are varieties of conditions. This time we have been in a humid area in front of Bwindi Impenetrable Forest.

That is how camp life at gold mining site looks like. There are varieties of conditions. This time we have been in a humid area in front of Bwindi Impenetrable Forest. - 2020-05-02: Passage of cattle over the river Rohezanyinda

Cattle has to pass the river just as always. There is no adequate bridge and it easily comes to animal abuse. We have to remember that we are just in front of the Bwindi Impenetrable Forest and it means end of civilization. Only gorillas and elephants and other larger or smaller animals may be found just 30 meters from this place straight to Congo.

Cattle has to pass the river just as always. There is no adequate bridge and it easily comes to animal abuse. We have to remember that we are just in front of the Bwindi Impenetrable Forest and it means end of civilization. Only gorillas and elephants and other larger or smaller animals may be found just 30 meters from this place straight to Congo. - 2020-05-02: Video for Andrea from Italy

This video shows how we were passing the river. We heard of people dying in this river although it is very shallow. Our assistant once saved a person from Rwanda who fell into river. The most important loss for that person was his mobile phone. The fact that he was saved and that he could get seriously injured or worse, he did not considered. This is gold bearing river.

This video shows how we were passing the river. We heard of people dying in this river although it is very shallow. Our assistant once saved a person from Rwanda who fell into river. The most important loss for that person was his mobile phone. The fact that he was saved and that he could get seriously injured or worse, he did not considered. This is gold bearing river. - 2020-05-02: Demonstration of Villa Grazia by our Italian manager

Villa Grazia is the cabin where our Italian manager was sleeping. Elephants were passing just by. Inside of the cabin there is tent for better protection from humidity and insects.

Villa Grazia is the cabin where our Italian manager was sleeping. Elephants were passing just by. Inside of the cabin there is tent for better protection from humidity and insects. - 2020-05-02: Surface mining pit covered with water

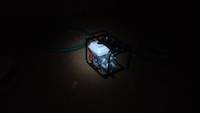

This pit is covered with water. It may be pumped out within few hours with water pump capacity of about 30 cubic meter per hour.

This pit is covered with water. It may be pumped out within few hours with water pump capacity of about 30 cubic meter per hour. - 2020-05-02: Demarcation of the mining site and latrine in background

One may see demarcation of the mining site and latrine in background.

One may see demarcation of the mining site and latrine in background. - 2020-05-02: Welcome to Villa Grazia: The Ultimate Timber Retreat

Villa Grazia was the cabin for our Italian manager. Site is located right in front of Bwindi Impenetrable Forest in Uganda.

Villa Grazia was the cabin for our Italian manager. Site is located right in front of Bwindi Impenetrable Forest in Uganda. - 2020-05-02: Living cabin in the middle of the mining site

We had elephants passing nearby this cabin each in a while as they come out of the Bwindi Impenetrable Forest in Uganda and go to sweet potato fields for a meal.

We had elephants passing nearby this cabin each in a while as they come out of the Bwindi Impenetrable Forest in Uganda and go to sweet potato fields for a meal. - 2020-05-02: Living cabin in the middle of the mining site

This cabin was used for sleeping by our manager from Italy. As we were just in front of Bwindi Impenetrable Forest we had elephants passing and sometimes touching the cabin during passage.

This cabin was used for sleeping by our manager from Italy. As we were just in front of Bwindi Impenetrable Forest we had elephants passing and sometimes touching the cabin during passage. - 2020-05-02: Mining pit covered with water with Bwindi Impenetrable Forest in background

One may see our first mining pit on this site #1 just about 100 meters in front of the Bwindi Impenetrable Forest in Uganda in the district of Kisoro. Start Your Own Gold Mine program is available in every country where gold may be mined.

One may see our first mining pit on this site #1 just about 100 meters in front of the Bwindi Impenetrable Forest in Uganda in the district of Kisoro. Start Your Own Gold Mine program is available in every country where gold may be mined. - 2020-05-02: Tent and cabing, behind view

One may see that some parts of sluices we have been keeping outside of the cabin. By the law we had freedom to use the spaces anywhere around the cabin. Yet some of landlords complained and demanded money which we did not pay.

One may see that some parts of sluices we have been keeping outside of the cabin. By the law we had freedom to use the spaces anywhere around the cabin. Yet some of landlords complained and demanded money which we did not pay. - 2020-05-02: Main cabin and storage

The cabin also serves as storage as in this left part of the cabin we have been accommodating a manager and apprentice plus all the shovels, gumboots, pickaxes, and other mining gear.

The cabin also serves as storage as in this left part of the cabin we have been accommodating a manager and apprentice plus all the shovels, gumboots, pickaxes, and other mining gear. - 2020-05-02: Main cabin protected by tarpaulin

The main cabin has been used by managers. It is protected from rain by the blue tarpaulin on picture. All communication and energy resources are stored in the main cabin with the essential food, computers and gold prospecting gear.

The main cabin has been used by managers. It is protected from rain by the blue tarpaulin on picture. All communication and energy resources are stored in the main cabin with the essential food, computers and gold prospecting gear. - 2020-05-02: Large camping tent

The large camping tent sometimes accommodated even 6 to 8 people. When set on right place it offers quite a good protection from humidity, rain and eventual wind.

The large camping tent sometimes accommodated even 6 to 8 people. When set on right place it offers quite a good protection from humidity, rain and eventual wind. - 2020-05-02: Water tanks used as storage for food and shower tent in background

You may see water tanks on this picture. We are using them normally for water. In this camp we have been using them to store food and dishes. In background one can see our shower tent. The tent is very practical device allowing us to shower even surrounded by other people. This item is very recommended in the program Start Your Own Gold Mine.

You may see water tanks on this picture. We are using them normally for water. In this camp we have been using them to store food and dishes. In background one can see our shower tent. The tent is very practical device allowing us to shower even surrounded by other people. This item is very recommended in the program Start Your Own Gold Mine. - Meetings during Preliminary Site Assessment and Inspection in Busia, Uganda for gold mining startups

2020-09-28 - We are continually conducting meetings with gold mining site owners, and arranging appointments and conducting Preliminary Site Assessment and Inspection to determine in a quick manner how small scale gold mining activities may be improved. East African small scale gold mining industry will be good opportunity for investments for long term.

2020-09-28 - We are continually conducting meetings with gold mining site owners, and arranging appointments and conducting Preliminary Site Assessment and Inspection to determine in a quick manner how small scale gold mining activities may be improved. East African small scale gold mining industry will be good opportunity for investments for long term. - How to chat with Start Your Own Gold Mine staff members?

We are using the Extensible Messaging and Presence Protocol (XMPP) as our main and private communication protocol. It enables near-real-time chat or messaging with exchange of files, images, data and geographical locations between our staff members. Set up your software on any mobile device or any operatin system and you will be soon ready to go to chat with us.

We are using the Extensible Messaging and Presence Protocol (XMPP) as our main and private communication protocol. It enables near-real-time chat or messaging with exchange of files, images, data and geographical locations between our staff members. Set up your software on any mobile device or any operatin system and you will be soon ready to go to chat with us. - 2020-01-18 Day of gold prospecting from Kampala, Uganda and 500 km to the West

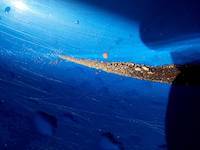

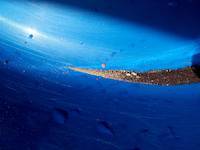

This was the day of gold prospecting straight from Kampala, Uganda and

then 500 km to the west. We arrived to the place which we are not

revealing at this place. Gold was confirmed several times on the first

gradient. That means after verbal gold prospecting we are arriving to

location and panning or making reports. On this location we found area

without license that can be licensed by us. It offers opportunity for

quick gold mining.

This was the day of gold prospecting straight from Kampala, Uganda and

then 500 km to the west. We arrived to the place which we are not

revealing at this place. Gold was confirmed several times on the first

gradient. That means after verbal gold prospecting we are arriving to

location and panning or making reports. On this location we found area

without license that can be licensed by us. It offers opportunity for

quick gold mining. - 2.47 grams of the gold on the balance scale

This is my other balance scale that measures up to 300 grams and is

very accurate. It cannot measure small particles less than 0.20 grams.

This is my other balance scale that measures up to 300 grams and is

very accurate. It cannot measure small particles less than 0.20 grams. - 0.23 grams of gold recovered from concentrate after the sluice run

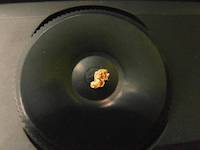

This is 0.23 grams of gold that we have recovered from concentrate

after the sluice run.

We are satisfied that our medium field prospecting sluice is not

losing any gold particles. The situation "not to lose" gold particles

is specific to this location, the particle shapes and sizes. If gold

particles would be smaller, we would need to utilize better special

methods. While we have almost 95% of gold particles that belong to

medium gold size group, we recover all gold that is present in the

excavated soil.

This is 0.23 grams of gold that we have recovered from concentrate

after the sluice run.

We are satisfied that our medium field prospecting sluice is not

losing any gold particles. The situation "not to lose" gold particles

is specific to this location, the particle shapes and sizes. If gold

particles would be smaller, we would need to utilize better special

methods. While we have almost 95% of gold particles that belong to

medium gold size group, we recover all gold that is present in the

excavated soil. - Gold Nugget Weighing 8.048 Grams

Mining area from April 2020 is yielding with gold at all times.

Mining area from April 2020 is yielding with gold at all times. - Gold Particles: 0.144 Grams on balance scale

This is how it looks like when gold is measured.

This is how it looks like when gold is measured. - 1.068 grams of natural gold nuggets on the balance scale

Nice natural gold particles on the scale.

Nice natural gold particles on the scale. - Natural Gold Nugget 2.4 Grams On Balance Scale

This is alluvial gold, natural gold nuggets on the balance scale.

This is alluvial gold, natural gold nuggets on the balance scale. - 0.062 grams of gold on the balance scale

We observe particles of gold on the balance scale.

We observe particles of gold on the balance scale. - 0.214 grams of gold of natural gold particles on the balance scale

We observe gold particles on the balance scale, we measure the gold and verify its values, this way miner gets the ability to conduct field assays.

We observe gold particles on the balance scale, we measure the gold and verify its values, this way miner gets the ability to conduct field assays. - 0.12 grams of gold on the balance scale

Observation of gold sizes and weights help the miner to determine better areas or estimate values in small scale mining.

Observation of gold sizes and weights help the miner to determine better areas or estimate values in small scale mining. - 0.078 grams of gold on the balance scale

This is how much gold one needs to reach 0.078 grams. Observations of quantity of gold and its weight and value is a process that helps the miner determine easier good gold bearing areas.

This is how much gold one needs to reach 0.078 grams. Observations of quantity of gold and its weight and value is a process that helps the miner determine easier good gold bearing areas. - 0.204 grams of natural gold particles on the balance scale

The balance scale is very precise, it is however limited to 10 grams

of precious stones or gold, or anything else.

The balance scale is very precise, it is however limited to 10 grams