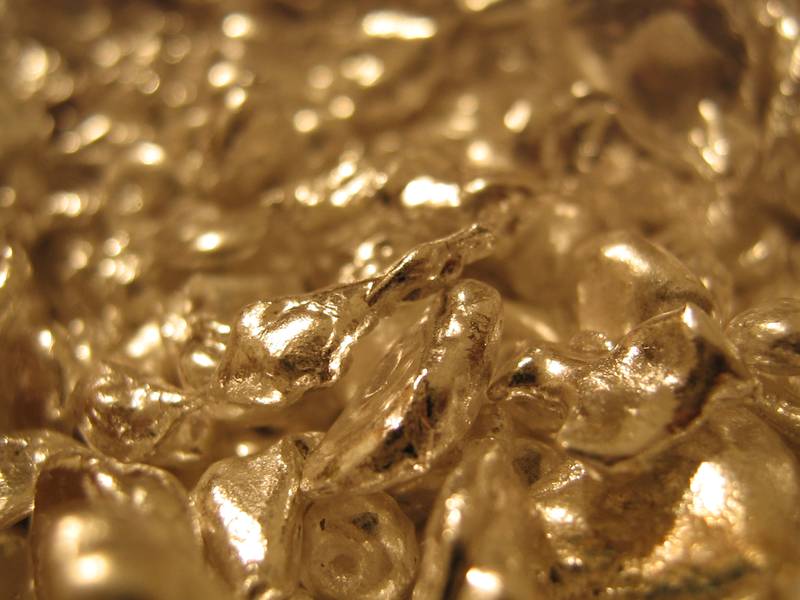

Close up of silver flake

The creation of silver flakes is a part of the electrolytic refining and purification process for fine metals, including silver. This method involves several steps to produce uniform, thin sheets or “flakes” that are highly pure:

Preparation: The first step in this procedure begins with impure silver (anode slimes) which is dissolved into a solution of nitric acid and water.

Electrolysis Setup: Then, the purified anodic solution serves as electrolyte for an electrorefining cell consisting of two main components: cathodes (where pure silver will be deposited) and anode(s). The setup also includes a power source to conduct electric current through the system.

Electrodeposition: When direct current is passed, positively charged hydrogen ions in solution migrate towards the negatively-charged cathodes (made usually of pure silver or platinum), where they gain electrons and get reduced back to their elemental form - molecular hydrogen gas. Meanwhile, silver ions from the anode dissolve into the electrolyte are attracted by negative charge on cathodes, lose electrons (are oxidized) and deposit as pure metal onto these surfaces in a process called reduction or plating.

Formation of Silver Flakes: The unique shape – thin flakes - is due to the specific conditions under which deposition occurs: high current density combined with an agitated electrolyte solution, often facilitated by rotating cathodes (drum cells). As silver ions arrive at these rapidly moving surfaces and reduce back into metallic form, they do so in a highly controlled manner that results in the formation of thin sheets or flakes rather than bulk deposits.

Separation: After electrodeposition is complete, the cathodes are removed from solution containing impurities remaining after refining (catholyte). The pure silver flakes adhere to these surfaces and can be easily peeled off or chemically dissolved in a subsequent process for further purification.

Final Purification: Finally, the harvested silver flakes undergo additional steps like melting followed by casting into bars (known as electrolytic bullion) to achieve even higher levels of purity if required before they’re ready for various industrial or commercial uses such as electronics manufacturing.

This process not only ensures high-purity silver but also produces a form that’s advantageous in many applications due to its large surface area relative to volume, facilitating better reactivity and reaction kinetics when used in chemical catalysis for example.